Overview of Drive Axle Shaft in Electric Vehicles

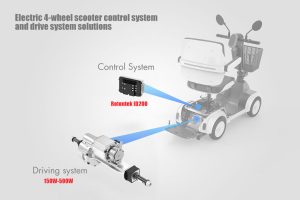

The drive axle shaft in electric vehicles (EVs) plays a critical role in delivering power from the electric motor to the wheels. Unlike traditional internal combustion engine vehicles, EVs rely on electric motors for propulsion, which changes the dynamics and requirements of the drive axle shaft.

Key Characteristics

Material and Quality

The drive axle shaft in EVs typically comprises high-strength steel or composite materials. These materials are chosen for their ability to withstand high torque levels generated by electric motors, ensuring durability and reliability.

Dimensions and Specifications

EV drive axle shafts vary in size and specifications depending on the vehicle model and design. However, they generally have a more compact and lightweight design compared to those in combustion engine vehicles. This is due to the reduced need for bulky transmission systems in EVs.

Power and Efficiency

Electric motors generate instant torque, which the drive axle shaft must efficiently transfer to the wheels. This demands a design that can handle high power levels – often in the range of 100 to 250 kW – while minimizing energy losses.

Functions and Advantages

Improved Efficiency

One of the main advantages of EV drive axle shafts is the improved efficiency in power transmission. The direct connection between the electric motor and the wheels via the shaft allows for more efficient use of energy, contributing to the overall efficiency of the vehicle.

Cost and Maintenance

The simplicity of the design in EV drive axle shafts often leads to lower manufacturing costs and reduced maintenance requirements. With fewer moving parts than traditional systems, the likelihood of mechanical failures decreases, potentially extending the lifespan of the vehicle.

Noise Reduction

Electric vehicles are known for their quiet operation. The drive axle shaft in EVs contributes to this by producing less noise compared to conventional vehicles, enhancing the driving experience.

Speed and Responsiveness

The drive axle shaft in EVs is designed to handle the immediate torque delivery from electric motors, resulting in quicker acceleration and responsive handling.

Limitations and Challenges

Cost Factors

While the initial manufacturing cost of the drive axle shaft in EVs can be lower, the overall cost of the vehicle is often higher due to the expensive battery systems.

Lifespan Concerns

The high torque levels can put significant stress on the drive axle shaft, potentially affecting its lifespan if not properly designed or maintained.

Technological Challenges

As EV technology evolves, the drive axle shaft must adapt to handle increasing power outputs and efficiency demands, which can pose design and engineering challenges.

In conclusion, the drive axle shaft in electric vehicles is a vital component that has evolved to meet the unique demands of electric propulsion. Its design and functionality significantly contribute to the efficiency, performance, and cost-effectiveness of EVs, while also presenting certain challenges and limitations that need to be addressed as the technology advances.